Deeper understanding of paramagnetic effects in NMR spectra of transition metal complexes

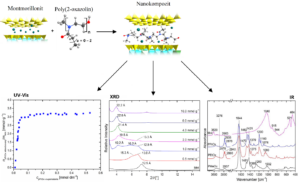

Nanomaterials based on clay minerals and poly(2-oxazolines)

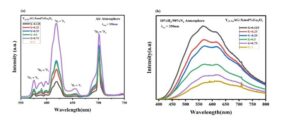

YAG: Eu microspheres for high-power LED colour converters

The photoluminescence emission spectra of microspheres YAG:Eu in different concentrations (a) before reduction, (b) reduced in 10% H2/N2 atmosphere

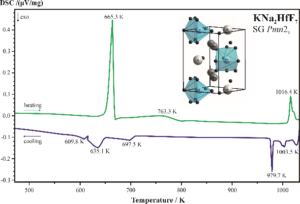

Complexity of the KNa2ZrF7, KNa2HfF7 and KNa2(Hf,Zr)F7 compounds

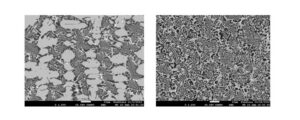

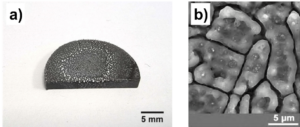

A method for producing eutectic ceramics composites based on the pseudo-ternary system of Al2O3-Al3Y5O12-ZrO2

Scanning electron microscope photograph of (a) the produced mixed laminar-ordered structure and (b) the produced Wootz steel complex structure

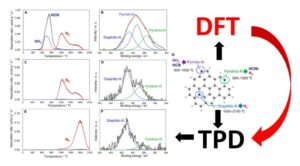

Combined study of gas desorption processes at high temperatures in N-doped graphene

Fig. 1. Case study application of the TPD method for various N-containing carbons. TPD profiles and N 1s XPS spectra of porphyrin-derived carbons.

(A–F) (A and B) Py_600, (C and D) Py_1100 and (E and F) N-containing coke. (G) Sources of desorption products as a function of pyrrolic-, pyridinic-, and graphitic-N species.

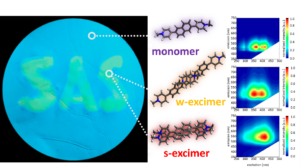

Stimuli-responsive optical features of naphthalene core dication confined in 2D material

Photoluminescence image of the inscription “SAS” made with DMSO on the surface of a thin-film sample (λex = 365 nm). Inset: lanternfish (©BluePlanetArchive/David Wrobel)

Development of B4C-SiC composites with improved high temperature properties

Fig. 1: a) surface of the B4C composite with 5 hm.% SiC fibres after oxygen-acetylene flame treatment at 1800°C; (b) SEM image of the surface of B4C-SiC composite after laser ablation at temperature exceeding 10 000 K.

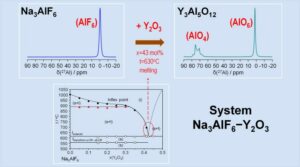

Determination of the Na3AlF6–Y2O3 Phase Diagram and its Implications for Low – Temperature YAG / Nd:YAG Synthesis

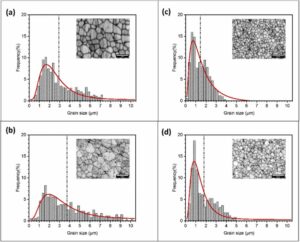

Liquid phase sintering: an approach to produce fine-grain ceramics immune to grain growth

Contact

Contact Intranet

Intranet SK

SK